- Sustainability

- Hydrogen and Power-to-X

Hydrogen and Power-to-X Solutions

A New Ecosystem of Low-Carbon Fuels

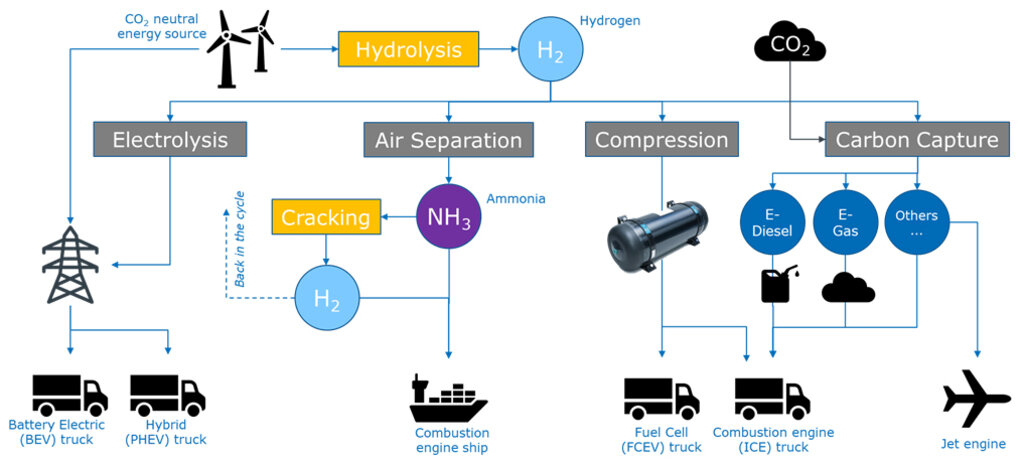

Power-to-X is an ecosystem of opportunities to store and distribute energy to a wide range of applications – from old, existing Internal Combustion Engines (ICEs), to high-tech Fuel-Cell Electric Vehicle (FCEVs). Green Hydrogen (H2) is at the center of it all and can be used as either a simple energy carrier, directly as a fuel for both ICEs and FCEVs or as an ingredient for producing additional fuels such as Ammonia or synthetic e-fuels.

Dinex’s innovations can be applied in several areas of the Power-to-X system, and we took part already in development projects with partners and customers to ensure that these new technologies remain clean.

Pipe solutions for Fuel-Cell Electric Vehicles (FCEV)

The only exhaust emissions from an FCEV vehicle are process water and water vapor. This calls for exhaust pipes in order to lead it away from the fuel cell to a favorable point of exit. To prevent freezing and condensing of the vapor, piping needs to be heated and insulated. Dinex has been supplying exhaust pipe solutions for 40 years, including also decoupling elements, clamps, and insulation technologies, and are together with major Heavy Duty OEMs participating in development programs for serially produced exhaust pipes for FCEV application.

.jpg)

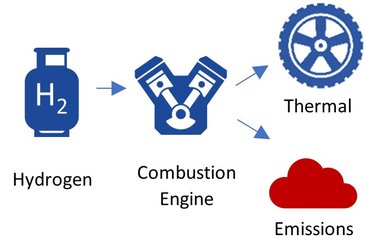

Hydrogen Combustion Engines (H2-ICE)

FCEV-powertrains are still an expensive and rather immature technology – and furthermore, it performs poorly in very dusty environments such as construction sites. But Green Hydrogen can also work as a fuel in a simple, slightly modified gas engine – and it gives the same decarbonization effect. The trade-off is mainly emissions of NOX and a small number of ultrafine particles. Dinex is already supplying SCR-systems and Particulate Filter solutions for Euro VI applications all over the world, and our expertise is used by a number of Off-Road OEMs who are preparing engine ranges to run on Hydrogen.

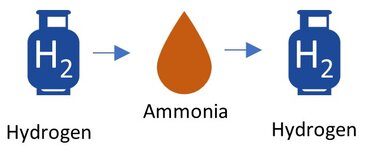

Ammonia Cracking

With Hydrogen being the central element of the Power-to-X concept, storage and distribution of this otherwise extremely volatile material become vital. Hydrogen can rather simply be converted into liquid Ammonia (NH3), packing much more energy in lesser space, making it easily transportable and even useful as a fuel in large combustion engines such as those found in marine applications. When transported to its destination location, Ammonia can be converted back into Hydrogen using a cracking process, and here Dinex’s catalyst and canning experience is already proving useful for setting up efficient facilities enabling a more flexible and scalable energy distribution network in the PtX-concept.

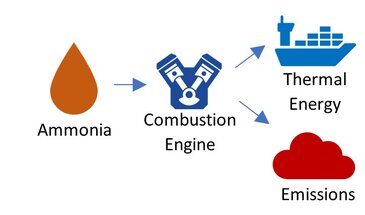

Ammonia Engines

Ammonia (NH3) produced from Green Hydrogen is a promising carbon-neutral fuel for especially large 2-stroke marine engines due to the very high energy density and typically very long journeys. Combustion of Ammonia leads to thermal NOX emissions, and the most efficient way of reducing these is via an SCR system. Dinex’s extensive automotive experience is already well applied in several marine applications already. Our substrate technology is fully scalable to all sizes and geometries, and our coating formulas are adaptable to a wide range of fuels.