- Innovation

- Decarbonisation

Decarbonisation

Dinex supports decarbonization of the transport and energy sector by applying its decades of experience in catalysts for clean mobility, into catalysts that support greener transportation and energy infrastructures.

Catalyst Coated Membranes

At Dinex, we are proud to be at the forefront of this remarkable technology. Our catalyst coated membranes (CCMs) are paving the way for a sustainable and efficient future. With our expertise, dedication, and cutting-edge solutions, we are shaping the landscape of fuel cell technology.

Why Catalyst Coated Membranes? Catalyst coated membranes (CCMs) are at the heart of fuel cell systems. As a critical component, CCMs facilitate the electrochemical reactions that convert hydrogen and oxygen into clean electricity and heat. Our CCMs offer superior performance, durability, and efficiency, ensuring optimal power generation and utilization.

The Dinex Advantage

At Dinex, we are committed to delivering excellence in every aspect of our catalyst coated membranes. Here's why customers choose Dinex:

Advanced Formulations: Our state-of-the-art catalyst formulations maximize activity and efficiency, ensuring optimal fuel cell performance.

Cutting-edge Coating Processes: With our expertise in coating technologies, we achieve precise and uniform catalyst distribution on the membrane, enhancing durability and longevity.

Quality Assurance: Rigorous testing and quality control measures guarantee that our CCMs meet the highest standards of performance and reliability.

Customization: We offer tailored solutions to meet specific customer requirements, enabling seamless integration into various fuel cell systems and applications.

Applications

Our catalyst coated membranes find applications across diverse sectors, including:

- Transportation: Fuel cell-powered vehicles, buses, trucks, and drones.

- Residential: Clean and efficient power generation for homes and communities.

- Industrial: Reliable and sustainable energy solutions for manufacturing processes.

- Portable Power: Compact and lightweight fuel cell systems for remote and off-grid applications.

Unleash the Power of Fuel Cells with Dinex. As you explore the possibilities of clean energy, trust Dinex to provide catalyst coated membranes of unparalleled quality and performance. Join us in shaping a sustainable future, powered by fuel cell technology.

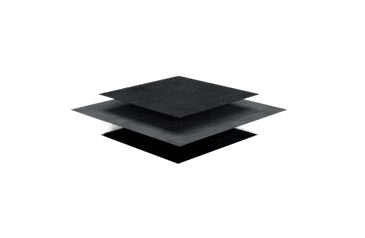

3-layer MEA: membrane plus catalysts on the anode and the cathodes side to enhance electrochemical reactions

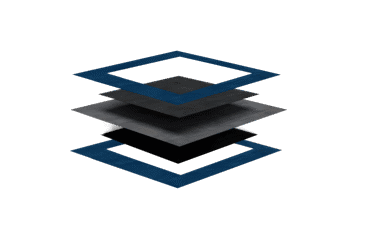

5-layer MEA: membrane plus catalysts on the anode and the cathodes side including subgasket support on both sides

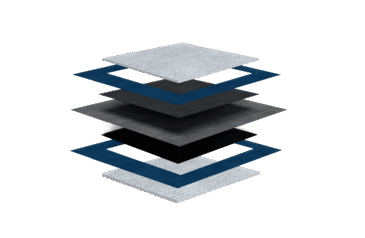

7-layer MEA: membrane plus catalysts on the anode and the cathodes side including subgaskets and gas diffusion layers on both sides

Ammonia Cracking

Unlocking Sustainable Hydrogen Production. A Pathway to Clean Energy.

In the quest for sustainable energy solutions, ammonia cracking has emerged as a groundbreaking process for large-scale hydrogen transportation and production.

Ammonia cracking is a catalytic process that breaks down ammonia (NH3) into hydrogen (H2) and nitrogen (N2) gases. This reaction occurs at elevated temperatures, typically in the presence of a metal catalyst. The resulting hydrogen can then be utilized in fuel cells, industrial processes, and various applications that require a clean and reliable source of energy.

Advantages of Ammonia Cracking Ammonia cracking offers several key advantages:

- Abundant Feedstock: Ammonia is readily available and can be produced from renewable sources or through traditional methods, providing a reliable and sustainable feedstock for hydrogen production.

- High Energy Density: Ammonia contains a high hydrogen density, making it an excellent carrier for hydrogen, enabling efficient storage, transportation, and utilization.

- Low Carbon Footprint: Ammonia cracking can be an environmentally friendly process when coupled with green hydrogen production methods, as it produces no greenhouse gas emissions.

- Scalability: Ammonia cracking can be easily scaled up to meet varying demand levels, making it suitable for a wide range of applications, from small-scale to large-scale hydrogen production.

Applications of Ammonia Cracking Ammonia cracking has diverse applications in industries such as:

- Energy Generation: Producing hydrogen for fuel cells, which power vehicles, stationary power systems, and portable devices.

- Industrial Processes: Providing a clean and reliable source of hydrogen for industries such as chemical synthesis, metal processing, and refining.

- Energy Storage: Facilitating the storage of excess renewable energy by converting it into hydrogen for later use or grid injection.

- Sustainable Agriculture: Offering a potential pathway for utilizing ammonia produced from agricultural waste to generate hydrogen, fostering circular economy practices.

Unlock the power of ammonia cracking with us as pioneers in the field of ammonia cracking, we are committed to advancing clean energy solutions. Join us in harnessing the potential of hydrogen to drive the transition towards a sustainable and low-carbon future.