- Sustainability

- Circular Economy

In the footsteps of Circular Economy

Did you know that the solutions which are the best for our planet, is often also those that are best for your operating costs?

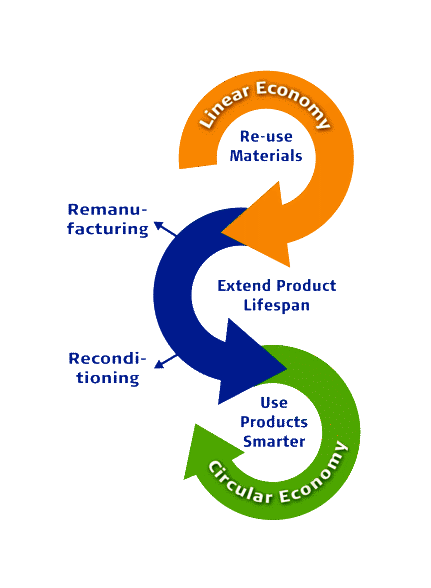

The “use-and-throw-away”-mentality of Linear Economy is on a retreat, and Circular Economy is gaining ground. The Automotive Aftermarket is no exception, and Dinex is ready with products and services that supports this movement while still putting all the advantages of lower costs, simpler solutions, and better quality, in your hands.

If you’re not already familiar with concepts such as Remanufacturing and Reconditioning, then it’s about time to get you introduced.

What is Remanufacturing?

Definition: To restore the functionality of a broken product, by replacing only the faulty parts.

Application: Euro IV, V and VI silencers.

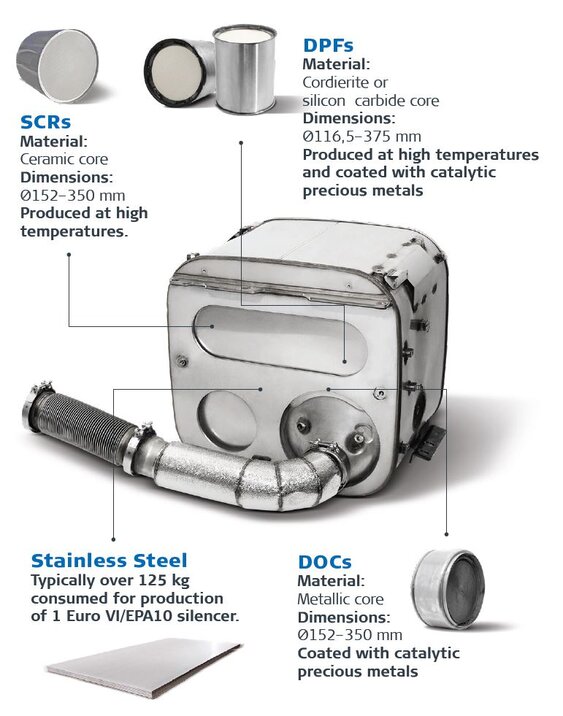

Your Euro VI / EPA10 silencer – or OneBox – is like a miniature truck-mounted chemistry factory. It‘s a complex system of catalysts and particulate filters all working together with the injection of AdBlue®/DEF, to reduce over 95% of harmful pollutants in the exhaust gas. Luckily it is a durable unit that rarely needs replacement, but if it does it can be a costly affair, and the production of new units has a significant environmental and climate footprint.

Remanufacturing of faulty Euro VI / EPA10 silencers is possible for most of the typical failures that you may encounter – and it is in most cases significantly cheaper than buying a new unit. Although it is a complex task to disassemble such units in order to e.g. replace a faulty Diesel Oxidation Catalyst (DOC) or Selective Catalytic Reduction (SCR) substrate, we see more and more specialized service providers appearing in Europe and North America. Due to the nature of the task it is always recommended to consult such a service, rather than to attempt remanufacturing on your own hand. Set demands to both competence level and quality of spare parts, since poor remanufacturing can result in damage to other components, loss of vehicle efficiency, or even legal actions and fines in case of non-compliance to emission regulations.

A Euro VI / EPA10 silencer is making a huge difference in clean mobility of modern trucks. But environmentally and climate wise it is an intensive product to produce. So make the most of it, with Remanufacturing and Reconditioning.

Why use Dinex replacement substrates for remanufacturing?

Dinex is actively supporting the remanufacturing movement by offering a complete range of high-quality, type-approved emission components for Euro VI and EPA 10 units. All our substrates, from Diesel Oxidation Catalysts (DOCs), Selective Catalytic Reduction units (SCRs) and Diesel Particulate Filters (DPFs), are developed and produced by Dinex, and has been tested and validated to offer you best match between

performance and price. Furthermore, we provide technical guidance and advisory to several local service providers of remanufacturing, building up their competence level so they can provide you with a faster and better service.

We can do this, because we are a global partner to some of the world’s leading OEMs, and we know the chemistry behind the substrates as well as the importance of maintaining the right design, the right flow, and the right materials of these systems.

This is your guarantee for getting the most benefits out of your remanufactured unit, and continued compliance to the emission regulations that apply to your vehicle.

Dinex is an active member of the Automotive Parts Remanufacture Association (APRA) in both Europe and North America, which is a non-profit organization that promotes and supports the economic, social, and environmental benefits of this industry.

Remanufacturing is a job for specialised workshops. With Dinex components you are guaranteed to restore the Emission system’s full performance while maintaining full compliance to legislative requirements.

What is Reconditioning?

Definition: To restore a used product back to a near-new state of functionality.

Application: Diesel Particulate Filters.

A Diesel Particulate Filter (DPF) traps more than 99% of particulate matter and ultrafine particles in the exhaust gas, practically removing more particles than already present in the ambient air in which the vehicle typically operates. To prevent blockage of the filter, it is treated with a catalytic coating that regenerates the filter: Particles are incinerated and reduced to ash so that the filter can maintain it’s function over tens of thousands of driven kilometers – all depending on operating conditions.

But at some inevitable point in time, the filter has accumulated so much ash that the filter starts to cause back pressure in the exhaust system, and it needs to be removed. Here you have typically 3 choices: Install a new filter (expensive), clean the existing one, or swap your filter with a similar reconditioned filter.

Cleaning vs. Reconditioning - What’s the difference?

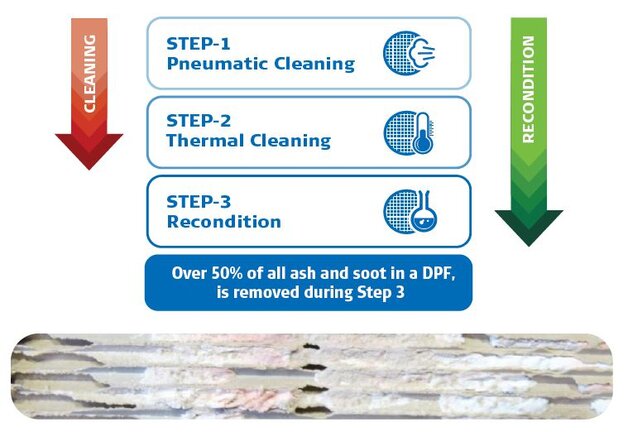

A simple 2-step cleaning of a Particulate Filter by a professional workshop removes most of the bulk ash and soot which are already relatively loose. That which remains is often loosened during the thermal cleaning step.

While this is often enough to lower the back pressure sufficiently to get back on the road, it does not restore the filter’s full functionality. Hardened ash typically remains in the surface of the filter even after thermal cleaning, where it acts like a glaze shading the catalytic coating and reduces the ability to regenerate. This will cost you in terms of increased back pressure, which leads to higher fuel consumption and lower engine performance – and shorter cleaning intervals, which leads to more downtime.

Hardened ash remaining in a filter after a 2-step cleaning process, resulting in more frequent cleaning, and higher fuel consumption.

Reconditioning is a third step in the cleaning process where chemical dissolvents are applied to remove the remaining hardened ash. This will restore the functionality of the catalytic coating, and bring the filter back to a near-new state of quality.

You will experience the same benefits of installing a new filter, in terms of fuel economy, engine performance, and cleaning interval – without having to pay for a new one.

Why use Dinex Recon-RX service?

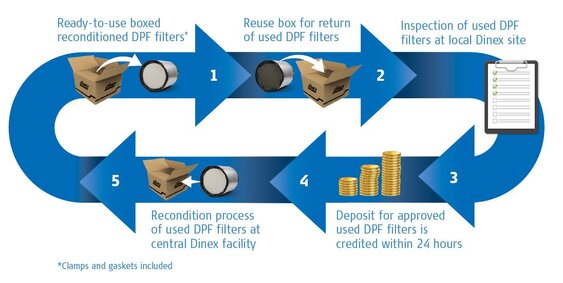

Through our extensive network of distribution centers, Dinex is offering a strong reconditioning service to customers in Europe and North America. We have a full-range program of reconditioned filters ready on stock at an attractive price compared to new filters, covered by a 2 years warranty period. Always delivered including all clamps and gaskets needed to make the filter replacement as fast and simple as possible.

The dirty filter can be returned to Dinex by re-using the same packaging, responsibly sealed using the included plastic bag, and a cash-back deposit is credited after successful quality inspection, within 24 hours of receival. The filter will then be processed at Dinex’ 3-step reconditioning line to fully restore it’s functionality and be re-sold as a Dinex Recon-RX filter to another customer. But you don’t need to worry about that, because you will already be back on the road taking care of your business.

Only filters which are type approved and which passes successfully through quality inspection will be accepted in the reconditioning loop, which is your guarantee for continued compliance to emission regulations. Using defective and nonapproved filters is illegal and may result in legal action and fines.

In any case, it is worth mentioning that re-using filters makes up to 95% lower CO2e footprint compared to producing new ones. But only with Reconditioning you will enjoy the full benefit of maximum fuel economy, and longer intervals between cleaning.

Dinex is stock-keeping of reconditioned Particulate Filters for all major truck brands and models available in the market.