- News and Events

- News

- 2021.08, From Green Field to Green Solution in 1 year

In April 2020, Ashok Leyland nominated Dinex for development and production of emission solutions for the recently introduced India Bharat Stage VI (BS-VI) compliant version of their H4 truck platform. With scheduled launch in February 2021, the challenge for Dinex was clear: All we had at the time, was one local employee, a technical proposal, and an empty space for a production site.

But in Dinex, finding solutions for customers is always the priority. Thanks to the remarkable effort and teamwork demonstrated by our global and local organization, we have 1 year after managed to:

- Develop a complete emission solution, customized for customer applications and requirements.

- Solved complex technical challenges by continuous innovation throughout the project execution

- Set up a local production Legal Entity from a Green field, ready for serial washcoat, coating, stuffing, welding, canning and assembly.

- Ready to service the customer.

- Setting up supplier base with successful PPAP of suppliers

All are projects that within the OEM industry very often may take several years. So how is it that Dinex was able to pull this off – all simultaneously, and even during a time of a pandemic? Let us dig into that.

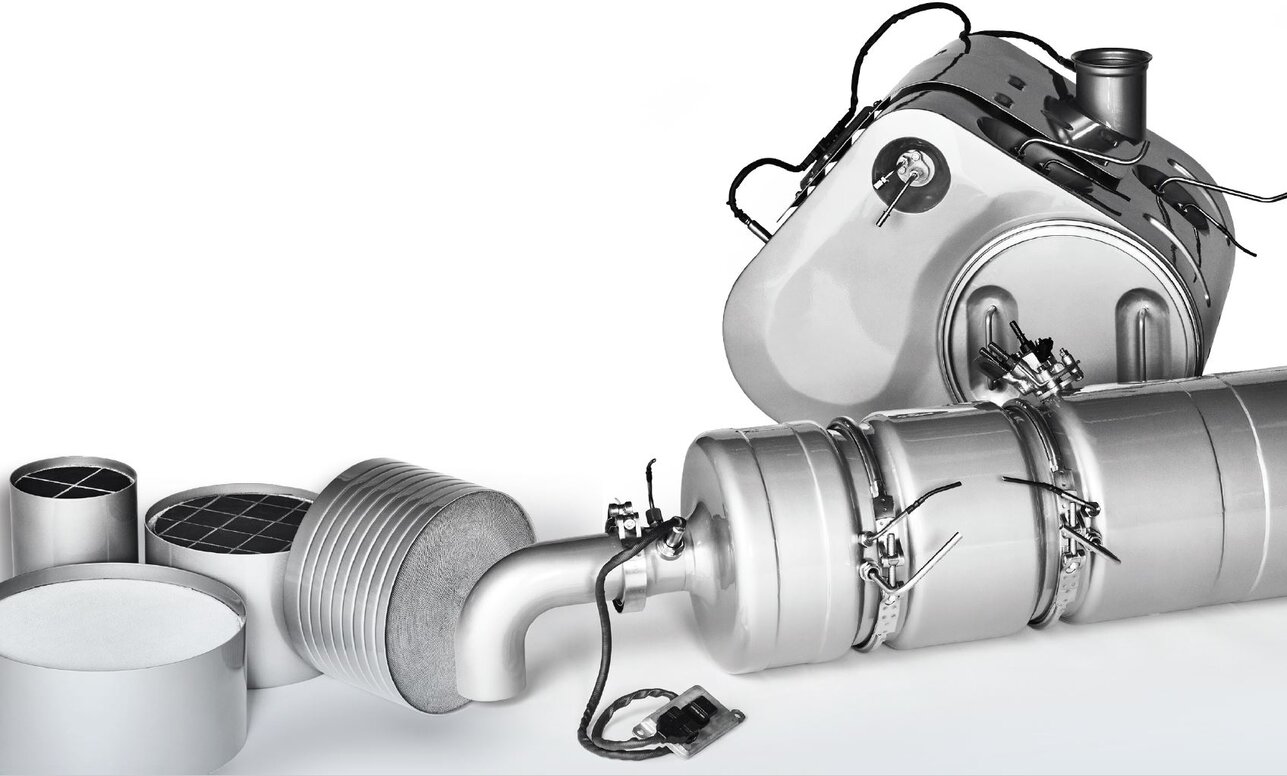

All Technologies under 1 Roof

Dinex is the only supplier in the Heavy Duty industry that holds competences for both development and production of all components of a complete emission solution in-house (Turbo to Tailpipe). Everything from design & simulations, up- and downstream piping, insulation and decoupling elements, to ceramic HPSiC & metallic substrates, coatings, and canning, is all based on Dinex’ own innovative technologies. And that includes also the competences required to put all the “bricks” together, to design, simulate, and finally test and validate the solution.

For developing a fully functional emission system, the only partnership we rely on is the one between ourselves and our customers. Our highly skilled R&D teams have the knowledge and experience to combine and adjust our technologies in a system that reaches the exact performance our customers expect to see – in a speed like never seen before. All thanks to quick decision making and complete in-house ownership of all core technologies.

Scalable Production Concepts and Strong Supply Chain

Dinex is already operating serial production of emission technologies in Europe, Russia, China and USA. By utilizing the knowledge and experiences of existing local teams to design and establish the new local production site in India – even before a local organization was fully established – we reduced lead time significantly. All is based on existing and well-known Dinex processes, combining our best experiences within both Lean philosophies and Industry 4.0 techniques to create a modern, efficient and stable shopfloor.

During Pandemic situations Dinex used digital AI platforms to validate tools, machines and suppliers. Strong relationship between suppliers helped to meet agreed timeline. Specially thanks to key strategic suppliers, government agencies and our team who worked to make it possible.

Agile, Global, Solution Oriented Culture

When all competences are joined together in the same organization, there is never any conflict of interest: The customer always comes first! We cannot move mountains – but we come pretty close.

Dinex’ internal processes ensure a robust and well-governed project execution. When working in full compliance with APQPmethodologies, and following IATF standards and principles, we are sure to never compromise quality.

But we also do not compromise time plans, and in full alignment with the customer – and thanks to an empowered Project Management, backed up by full organizational commitment to the project from all levels, and finally a clear alignment on priorities between local and global resources – we found a project model that made success imminent.

Dinex culture is all about “How we can do it, instead of “Why we can’t”. We always believe that there are more than one given solution” and we as organization keep looking for innovative ways to work smarter. Like for instance when we 3D-print prototypes, and cut months off the development time for even faster decision making.

What can we do for you?

There is no doubt that a project like this is not something that is done every day. But nevertheless, it demonstrates how Dinex is ready to Go the Extra Mile when our customers need us to. This takes more than simply strong commitment – it takes an organizational culture on all layers, dedicated to finding solutions, ready to think innovatively, and willing to show agility.

We are thankful for the support and trust that our customer Ashok Leyland has shown us since day 1 on this project, and I have nothing but the deepest respect for our organization who has managed to pull this off and present us with the results we see today. It shows that when we describe ourselves as Agile, Solution-Oriented, Innovative and Simplistic – it is more than just words.

Dinex is looking forward to the future collaboration with Ashok Leyland, and welcome new opportunities in India – and the rest of the world. Want to learn more about how Dinex can help you?

Evangelos Georgiadis

Chief Technical Officer (CTO)

evg@dinex.de

Lennart Rasmussen

Chief Sales Officer (CSO)

lra@dinex.dk