- News and Events

- News

- 2023.07, Dinex Turkey - 15 Years and still growing

Dinex’s largest production site is located north of Istanbul, Turkey. Since 2008 our colleagues there have been developing and producing pipes, decoupling-elements, thermal insulation, silencers and canning of Euro VI emission aftertreatment systems (ATS) for European Onand Off-Road OEMs in accordance with IATF requirements. This year they celebrate their 15th anniversary by expanding even further and adding additional capabilities to their offering.

State-of-the-art coating concept:

Now also in Europe

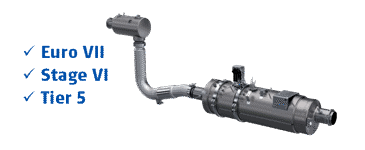

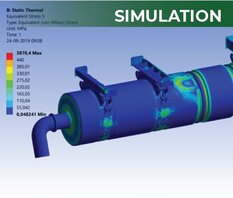

Dinex’ innovative production concept for catalytic coating has a proven track-record from the past years of service in China and India, equipping local leading OEMs with Euro VI equivalent solutions. The fully automated Industry 4.0 concept delivers a remarkably stable coating precision with Cpk-values above 1.67, while process optimizations ensure both a low and efficient energy consumption, and a very competitive cost structure. With the new setup in Dinex Turkey, we can offer our European OEM customers the same advantages, as the line is fully compatible with all applications for Diesel, Natural Gas and Hydrogen ATS systems for emission regulations up to Euro VII, Stage VI, and Tier 5.

Group COO Naresh Nagarwal together with the local team at Dinex Turkey to congratulate with a successful commissioning of the new coating line.

Growing full system capabilities to meet

the demand

With the exception of substrate manufacturing, the new coating capabilities compliments Dinex Turkey’s existing product offering perfectly and upgrades it from simple components to full emission solutions. With everything developed and produced under the same roof, Dinex Turkey can now offer customers unprecedented advantages in the form of a simpler supply chain, a more agile and flexible collaboration, and a more costefficient setup.

While OEMs are seeking to cut cost and complexity, we see a growing demand for a setup like this. Lately it has driven Dinex Turkey to a staff-count of over 600 employees, and output has grown by over 20% - but still with capacity for much more.

Are you curious about how Dinex can help you? Don’t hesitate to reach out to CSO Lennart Rasmussen for further questions and inquiries.

A glimpse of the Dinex OEM Division

Global Footprint - Local Presence

Operating with local teams close to our customers, backed up by global technical competences.

Core Technologies - Proven Solutions

All developed and produced in-house for a simple, cost efficient supply chain with highest solution ownership.

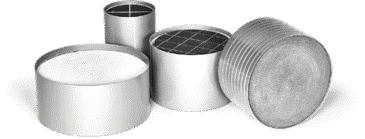

Ceramic and Metallic

Substrates with catalytic coating

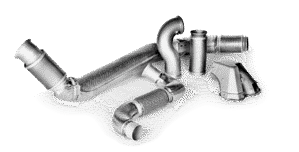

Pipes, Zero-Leakage Decoupling

and Thermal Management

Canning and system integration

with optimal flow and mixing

Agile Partnership - Customized Innovations

Full System and customer specific engineering approach: From final application down to coating formula.

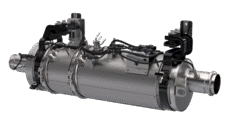

In-line system

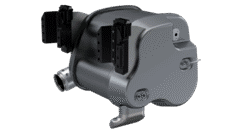

Box system

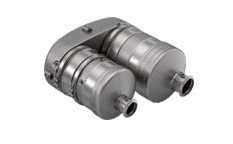

U-Shape system